Applications and References

Applications and References

Learn more about application examples for our Powerelements and see our successfully implemented reference projects for yourself!

For industries full of power

Powerelements in use

Application areas

Robust and powerful problem solvers: these are our PCB components. They are used wherever high currents are transmitted – especially in application areas such as:

- Power supply

- Signal & power transmission

- Mechanical fastening

- And more

Discover our extensive product range and premium services and successfully overcome your technological challenges.

Industries

PCB components from Würth Elektronik ICS are used worldwide across a wide range of industries and are valued by renowned international corporations just as much as they are preferred by niche and specialist providers. These include, among others:

- Automotive

- Electromobility

- Renewable energy

- Transport and logistics machinery

- Aerospace

- Industrial & mechanical engineering

- Robotics

- Household appliances

- Telecommunication and data communication

- Medical technology

- And many more …

Wide range of connecting solutions

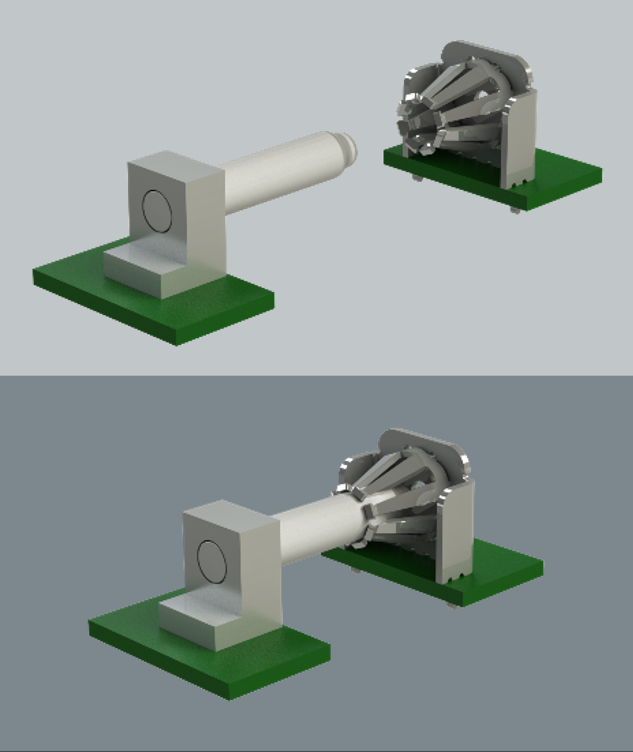

Contacting of a 3-phase motor with LF PowerBasket SMD

This application shows the contacting of a 3-phase motor, which is installed in an e-bike. A pluggable LF PowerBasket SMD 3 mm solution was chosen for the power supply. The LF PowerBasket SMD contacts are processed on conventional SMT lines, allowing cost-effective processing at high volumes.

The pluggable solution has the advantage of eliminating the need for additional terminals and screw connections, and the motor can be contacted directly.

This can be quickly and easily disassembled if required. The high position tolerance of this connector system, compared to other connector systems, makes it easy to use multiple contacts in parallel.

The mating connectors can be adapted to the motor and its installation conditions by the motor manufacturer on the basis of this interface description.

For this application, for example, the following LF PowerBasket article is suitable: K99763

Wire-to-board: Screw connection of a tubular cable lug with a (LF) PowerOne SMD bolt

A commercially available tubular cable lug (M6) of this type is used in practice, for example, in electric motors, construction machinery, elevators and wind turbines.

In this application example, the tubular cable lug is screwed into place with an (LF) PowerOne SMD bolt. Alternatively, when changing from SMT to press-fit technology, an (LF) PowerOne Press-fit or an LF PowerPlus bolt can be used. The (LF) PowerOne Powerelements are available in various designs and can be adapted to the tubular cable lugs you use for specific applications.

Bolting tubular cable lugs is done in a few steps

In the first step, the (LF) PowerOne SMD bolt is processed on a typical SMT line and soldered in an infrared oven or with the vapor phase system.

The tubular cable lug is then placed on the (LF) PowerOne SMD bolt and tightened with a standard M6 locking nut. This provides a quick and cost effective wire-to-board connection is possible.

Note: For proper processing, PCBs must be designed in accordance with the current edition of IPC A 600. Contact the Powerelement team for footprint information.

For this application, for example, the following (LF) PowerOne article is suitable: K97878

Mounting of a HV fuse 30 A with (LF) PowerOne bolts

In practice, this type of HV fuses is mainly used in practice in electric vehicles (EV) / hybrid vehicles (HEV), battery storage systems and battery chargers.

In this application, the mechanical and electrical connection of the DC high voltage fuse (30 A, 1000 V) to the PCB is made by two (LF) PowerOne bolts that are pressed into the PCB (SMT/THR/THT are also possible as an alternative). Instead of an (LF) PowerOne bolt, an LF PowerPlus bolt can also be used. The (LF) PowerOne bolts are available in different designs and can be adapted to the HV fuses used for the specific application.

HV fuses are mounted in 3 steps

First, the two (LF) PowerOne bolts are pressed into the printed circuit board. This creates a high performance, gas-tight electrical cold weld connection with extremely low contact resistance. The high voltage fuse is then positioned on the (LF) PowerOne bolts and screwed in place using commercially available nuts, lock washers and washers.

Note: For proper processing, it is necessary that the PCBs are designed according to the Würth Elektronik ICS Press-fit specification.

For this application, for example, the following (LF) PowerOne article is suitable: K91096

Contacting a 300 A HV fuse with (LF) PowerOne bushes

High voltage fuses of this type are mainly used in practice in electric vehicles (EV) / hybrid vehicles (HEV), battery storage systems and battery chargers.

In this application example, the DC high-voltage fuse (300 A, 1000 V) is connected to the PCB with two (LF) PowerOne bushes. The (LF) PowerOne bush can be of the press-fit, SMD, THT or THR type. Alternatively, LF PowerPlus bushes are also suitable for screwing on fuses.

The (LF) PowerOne bushes can be configured to suit specific applications and can therefore be adapted to different HV fuses.

The mounting of HV fuses is done in 3 steps

In the first step, the two (LF) PowerOne bushings are pressed into the PCB, e.g. with a simple toggle press. This creates a high performance, gas-tight electrical cold weld connection with extremely low contact resistance.

In the second step, the HV fuse is precisely positioned on the PowerOne bushes and screwed in place with standard M10 locking screws.

Note: For proper processing, it is necessary that the PCBs are designed according to the Würth Elektronik ICS Press-fit specification.

For this application, for example, the following (LF) PowerOne article is suitable: K97323

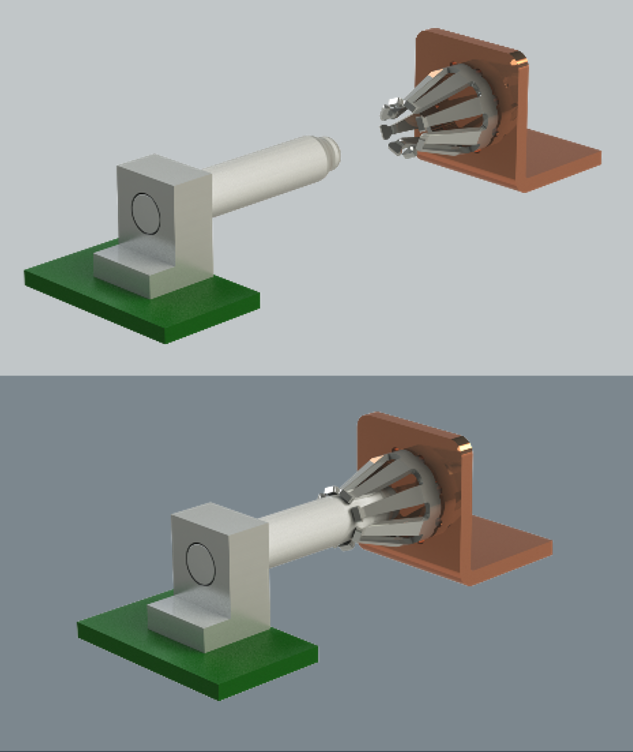

Bolting a busbar to a (LF) PowerOne bush

Busbars, also known as conductor rails, are usually made of copper or aluminum. Especially in the field of renewable energies, in the automotive industry (e.g. e-mobility) as well as in drive technology, busbars are used for the transmission of high electrical power.

The busbar is screwed on in just a few steps

In the first step, the (LF) PowerOne bush is pressed into the PCB or soldered onto the PCB as an SMD variant (THT & THR is also possible). Alternatively, the LF PowerPlus bushes can be screwed onto the busbar.

The busbar is then positioned on the (LF) PowerOne bush and screwed in place with a standard M6 locking screw.

Note: For proper processing, it is necessary that the PCB is designed according to the Würth Elektronik ICS Press-fit specification.

For this application, for example, the following (LF) PowerOne article is suitable: K91149

Mounting of an IGBT module with (LF) PowerTwo Powerelements

This type of IGBT is commonly used in electric vehicles, battery chargers and wind turbines.

In this application example, the IGBT module is contacted using two-piece (LF) PowerTwo Powerelements: a basic element and a press-in element. These Powerelements can be quickly and application-specifically adapted to the IGBT modules used. A major advantage is that the IGBT module is mounted without exerting pressure on the PCB.

The IGBT module is mounted in just a few steps

The first step is to press the (LF) PowerTwo base elements into the PCB. This creates a high performance, gas-tight, electrically cold welded connection with extremely low contact resistance.

In the second step, the matching press-in bushes are pressed into the base elements from the underside. The IGBT module is then plugged onto the PowerTwo high current contacts and screwed in place from below using commercially available locking screws.

Note: For proper processing, it is necessary that the PCB is designed according to the Würth Elektronik ICS press-fit specification.

For this application, for example, the following (LF) PowerTwo articles are suitable: K90506, K90500

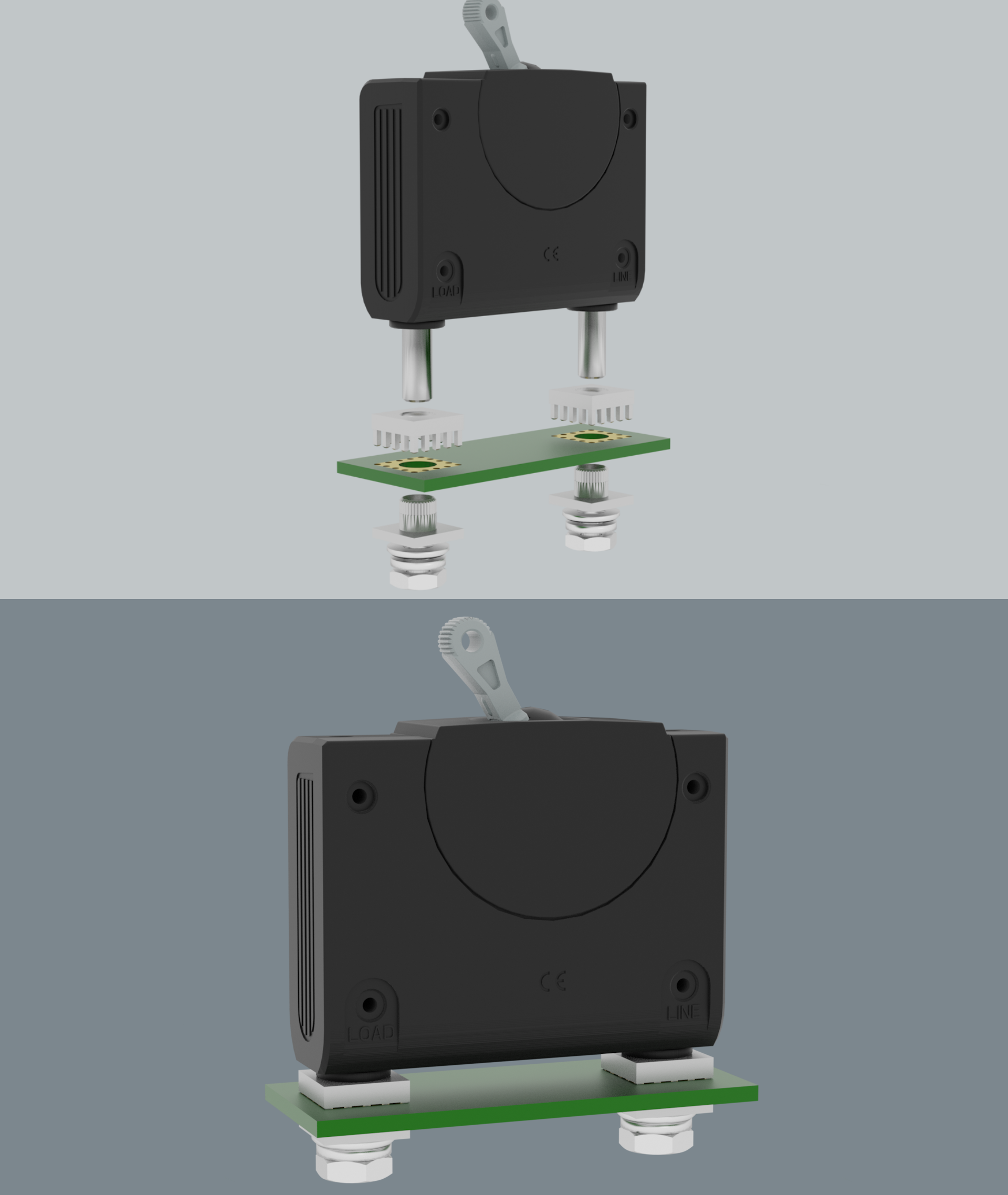

Mounting of a 1-pole circuit breaker with (LF) PowerTwo Powerelements

Single-pole circuit breakers with screw terminals (M6) are mainly used for power supplies in the automotive, renewable energy, medical technology and mechanical engineering industries. In particular, where characteristics such as durability and reliability play an essential role.

In this application, the mechanical and electrical connection of the miniature circuit breaker (60 A, 80 DCV, 1-pole) to the printed circuit board is made with two (LF) PowerTwo base elements and two press-in elements.

The two-piece Powerelements provide a permanent and reliable connection or fastening to the PCB without stressing the PCB itself. (LF) PowerTwo Powerelements are available in variety of designs and can be matched to the circuit breaker you are using for the specific application.

A circuit breaker is assembled in a few steps

The first step is to press the two (LF) PowerTwo base elements into the circuit board. This creates a high performance, gas-tight electrical cold-weld connection with extremely low contact resistance.

In the second step, the matching press-in bushes are pressed into the base elements from below. The circuit breaker with screw connection is then inserted into the (LF) PowerTwo Powerelements and screwed in place using commercially available nuts, spring washers and flat washers.

Note: For proper processing it is necessary that the PCB be designed according to the Würth Elektronik ICS Press-fit specification.

For this application, for example, the following (LF) PowerTwo article is suitable: K91074, K91071

Board-to-Board: Connecting two PCBs with a LF PowerBasket and an angled (LF) PowerOne Bolt

The connection of two PCBs is very common in practice. On the one hand, this can be done with a screw connection, but on the other hand, it can also be done with a plug-in connection. The advantage of plug-in connections over screw connections is that they are quick to assemble and easy to disassemble. Our LF PowerBasket Powerelements in combination with (LF) PowerOne Bolts are suitable for a plug-in board-to-board connection. The high position tolerance of up to 0.6 mm allows multiple LF PowerBaskets to be contacted simultaneously. A horizontal board-to-board connection can also be made using an angled (LF) PowerOne bolt and an LF PowerBasket Press-fit.

The Powerelements are mounted in a few easy steps

The angled (LF) PowerOne Bolt is pressed into the PCB or soldered to the PCB as an SMD variant (THT & THR also possible). The next step is to connect the LF PowerBasket to the PCB. The (LF) PowerOne Bolt can then be inserted into the LF PowerBasket to create the board-to-board contact.

For this application, for example, the following LF PowerBasket article is suitable: K902364

Busbar-to-Board: Connection between PCB and busbar using a LF PowerBasket and an angled (LF) PowerOne Bolt

Busbars are usually made of copper or aluminum. They are used for the transmission high electrical power, especially in the renewable energy sector, the automotive industry (e.g. e-mobility) as well as in drive technology.

With an angled (LF) PowerOne Bolt and an LF PowerBasket Press-fit Powerelement, a horizontal busbar-to-board connection can be made.

The Powerelements are mounted in just a few steps

The (LF) PowerOne Bolt is pressed into the PCB or soldered to the PCB as an SMD variant (THT & THR also possible). The LF PowerBasket Press-fit is pressed into a busbar.

The (LF) PowerOne pin can then be inserted into the LF PowerBasket to establish the busbar-to-board contact.

For this application, for example, the following LF PowerBasket article is suitable: K902364

Reference projects

Your Partner for intelligent solutions

Your Partner for intelligent solutions

We will be happy to advise you on which products will best serve your needs.

On request, we can also design and manufacture customized solutions for you.