PowerBusbar PCB

PowerBusbar PCB

For the extra power boost

Ideal for locally increased current flow on the PCB

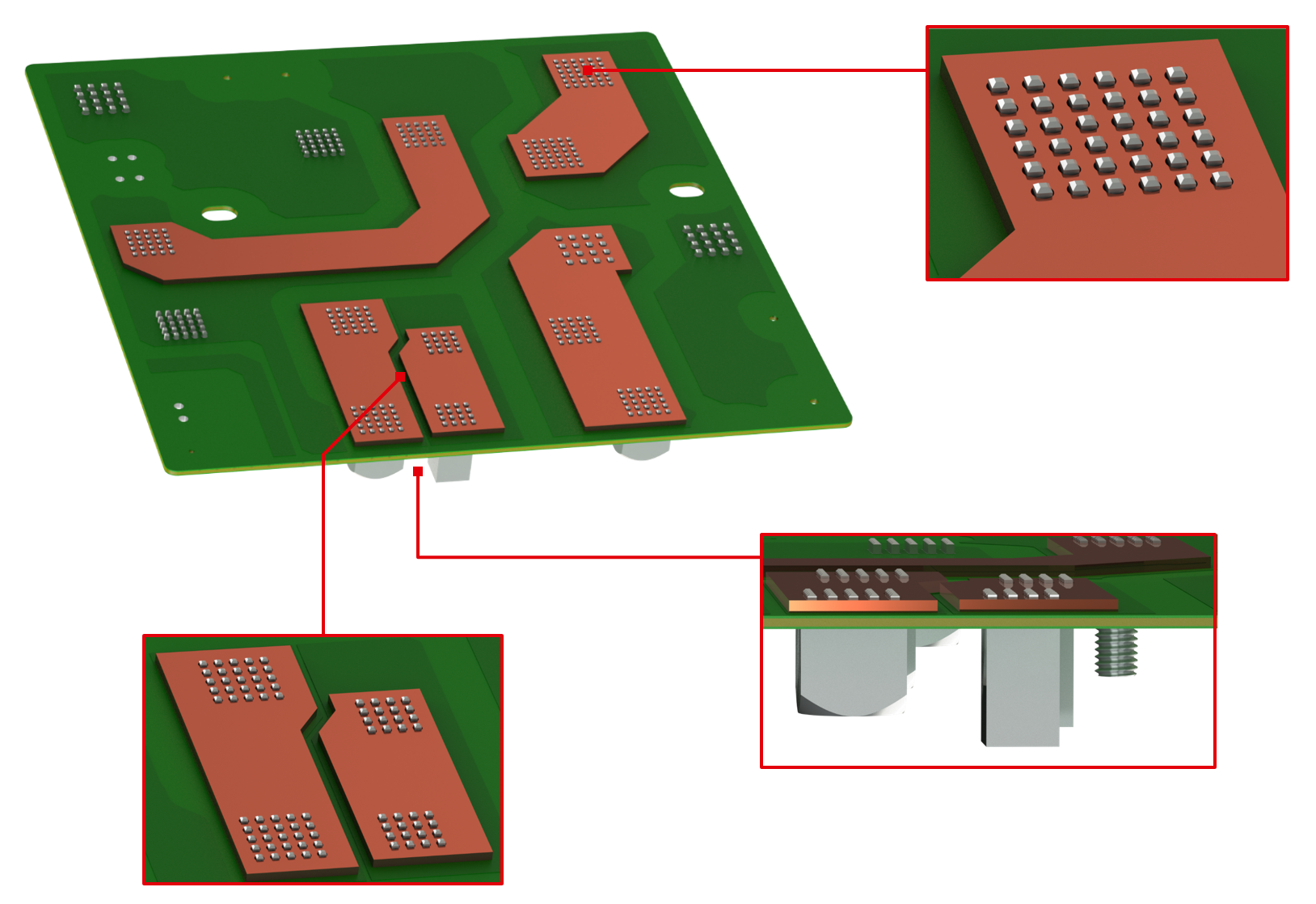

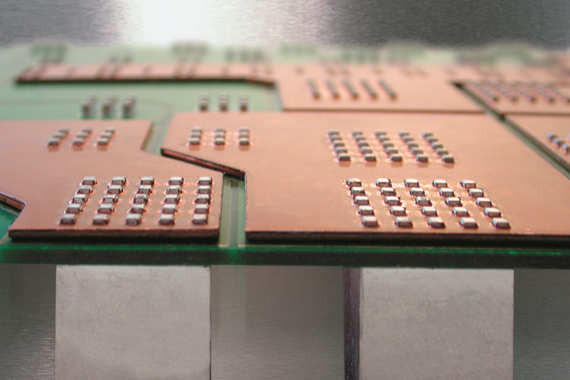

PowerBusbar PCB are copper busbars and are used especially where high currents need to be distributed precisely to PCBs. The copper busbars are pressed together with the Würth Elektronik ICS Powerelements – especially (LF) PowerOne Press-Fit or LF PowerPlus – and the PCBs in a single operation. The PowerBusbar design is provided by you as a sketch and laid out by us for production.

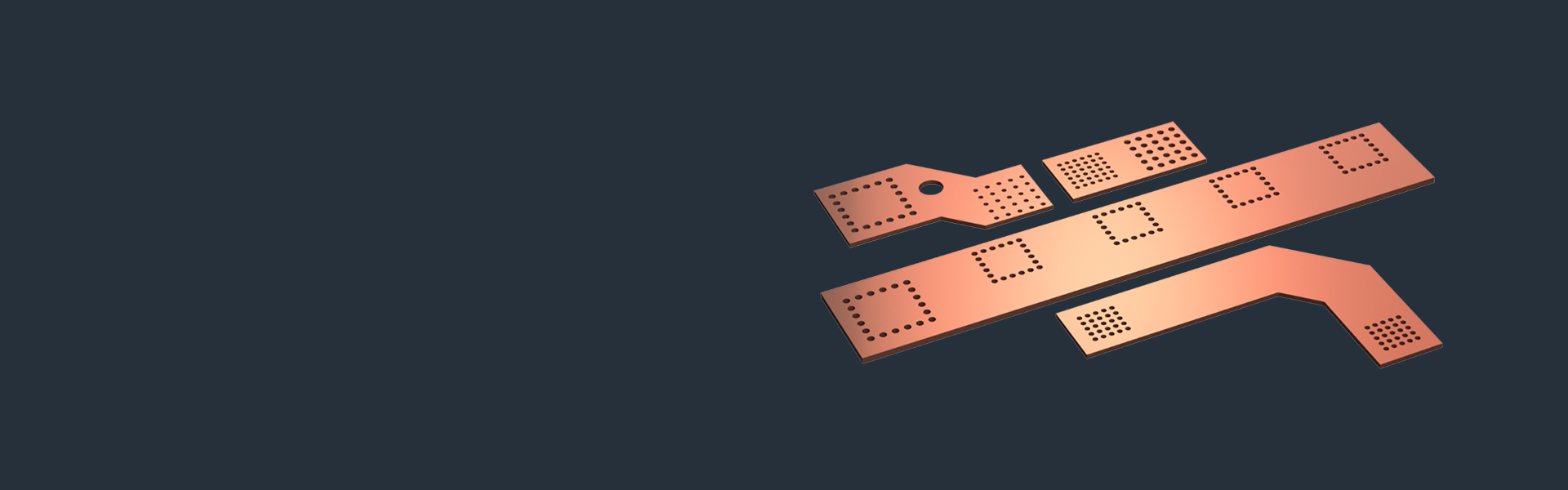

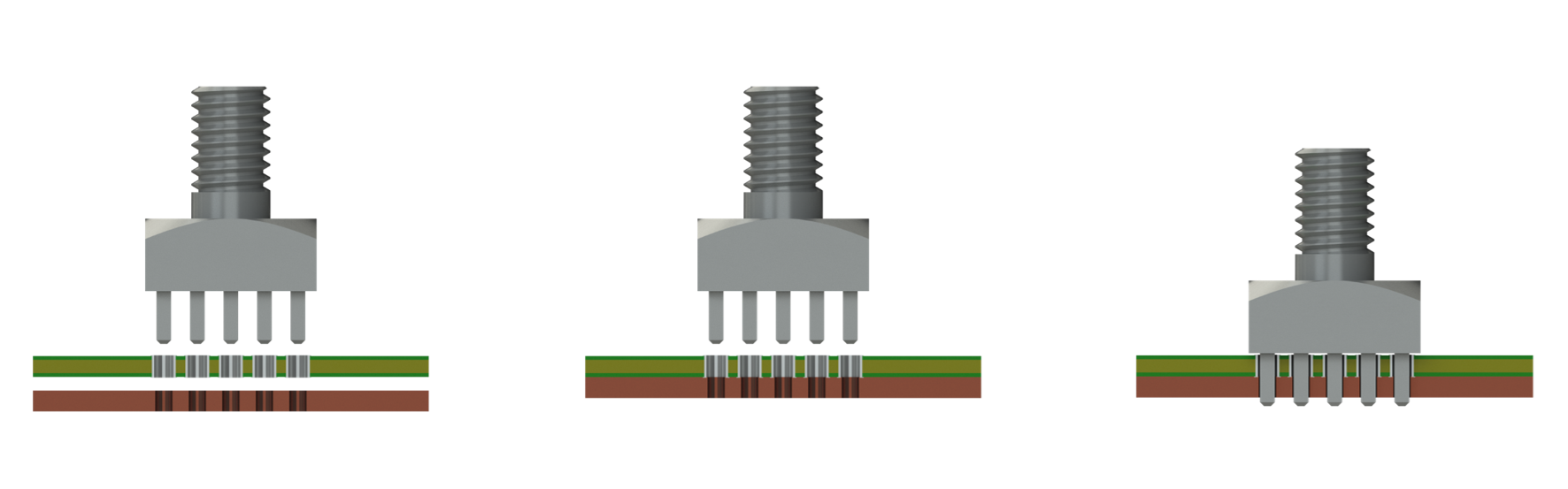

Design options for PowerBusbar PCB

The PowerBusbar PCB are always customized to suit the application and existing components, so there are no standard items. This allows a wide range of design options, examples of which are shown below.

Typical busbar thicknesses are 1.0 mm or 1.5 mm. The length, width and shape of the PowerBusbar PCB will depend on the project.

Interested? Contact our experts now and let us know your PCB layout for the creation of your PowerBusbar PCB. We will develop the right PowerBusbar PCB solution with the right Powerelement for your project!

Benefits of PowerBusbar PCB

- Local increase in current carrying capacity

The current carrying capacity of the printed circuit board can be increased locally and/or over a large area. - High current conductivity

PowerBusbar PCB are excellent current conductors and enable efficient and low-loss current transport. - High thermal conductivity

PowerBusbar PCBs efficiently dissipate heat from the overall system. This prevents hot spots and increases current carrying capacity and reliability. - Cost benefits

By using the PowerBusbar PCB with its high copper cross-section, cost-effective standard PCBs can be used. Thick copper PCBs or special PCBs with copper inlays can be replaced. - Integration and adaptability

The PowerBusbar PCB can be easily integrated into an existing system. This is due to the customized design of the copper busbars. - Simple installation

The PowerBusbar PCB are pressed into the PCB with the Powerelements in a single step. No additional assembly step is necessary. - REACH and RoHS compliant

Processing options for PowerBusbar PCB

- Align Powerelement, PCB and PowerBusbar to each other and press in

- Further information on the processing instructions for PowerBusbar PCB in conjunction with (LF) PowerOne or LF PowerPlus Powerelements can be found here.

MPFT (Massive Press Fit Technology)

Massive press-fit technology is the process of pressing solid pins into an electrically plated-through hole in a printed circuit board. Powerelements for press-fit technology have excellent mechanical and electrical properties, making them ideal for use in harsh environments such as high temperature fluctuations or vibration. The press-fit process creates a high performance, gas-tight cold welded connection with a contact resistance of just a few μOhm. This ensures very high current carrying capacity through low resistance contact points.

PCB design

Printed circuit boards must be designed in accordance with the latest edition of IPC A 600. In the case of solid press-fit technology, the PCBs must be designed in accordance with the Würth Elektronik ICS Press-fit Specification. Special attention should be paid to hole diameter and copper thickness.

Further information

Current carrying capacity

The current carrying capacity must be considered in the context of the overall system. It depends, among other things, on the PCB layout, the Powerelements, the design of the busbar or the connection of external supply lines. Our measurements have shown that the limiting factor is usually to be found in the layout of the PCB or the connection of external supply lines (contact resistance press-fit zone 100 – 200 μΩ).

Qualification

The PowerBusbar PCB technology has been used successfully for years in Würth Elektronik ICS system solutions and is used in various market segments. In this context, the systems have been successfully tested in accordance with the ISO 16750-3 to -5 standard, among others. The PowerBusbar PCB connection must always be considered in the context of the overall system and tested for applicability.