LF PowerBasket

Ideal for multiple plugging cycles with low plugging forces, high position tolerance and low weight requirements

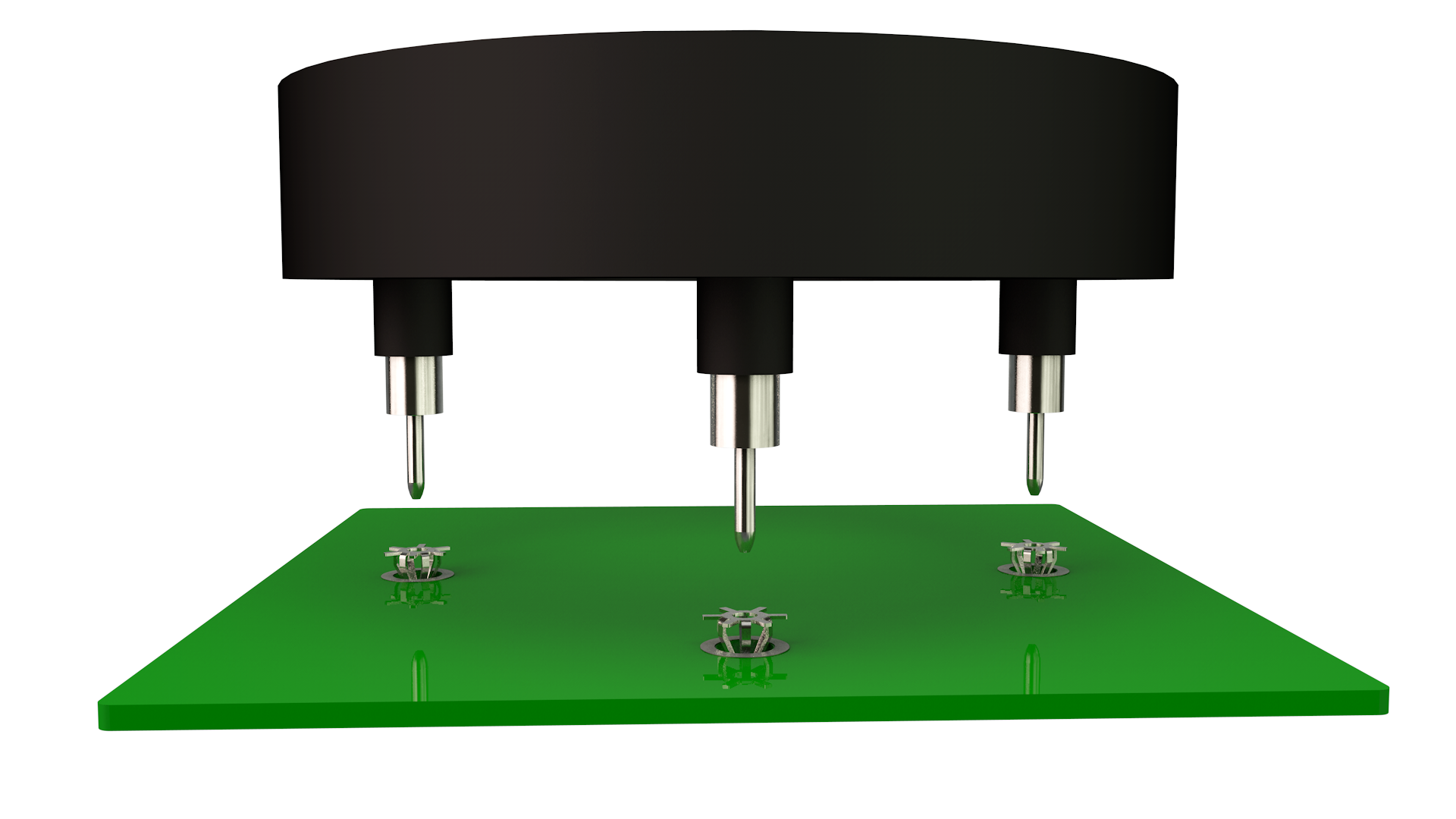

Lead-free, pluggable, just practical: Our LF PowerBasket high current PCB contacts are as flexible as your project: You can mount them using press-fit, SMT or THT technology – with significantly reduced assembly and maintaining effort. The special design of the contact spring also significantly reduces the insertion forces compared to other pluggable systems. Combined with a position tolerance of up to 0.6 mm, multiple can be used simultaneously. This opens up completely new applications, especially in the area of board-to-board connections – even up to a continuous operating temperature of 150 °C thanks to the special contact alloy. In addition to the baskets, you will also find the matching mating contacts.

Depending on the layout, currents of up to 150 Amps are possible.

Key information at a glance

Application possibilities

- Contacting of switches, fuses, etc.

- Wire-to-board

- Board-to-board

- Phase connection

From sample to market

Samples are available even in small quantities.

Just let us know what you need!

Packaging

Flexible packaging options: bulk, trays or in blister on reel for cost-effective assembly. In addition, you have the option to package the items in ESD blister tape, optionally with Kapton stickers or completely in your desired packaging.

Application possibilities

For wire-to-board, board-to-board connections and for contacting switches, fuses, etc.

Application possibilities

For wire-to-board, board-to-board connections and for contacting switches, fuses, etc.

LF PowerBasket Powerelements are ideal for wire-to-board and board-to-board connections, as well as for attaching components such as fuses or switches to the PCB. Learn more about these and other interconnect solutions now.

Processing options for LF PowerBasket Powerelements

MPFT (Massive Press Fit Technology)

Massive press-fit technology is the process of pressing solid pins into an electrically plated-through hole in a printed circuit board. Powerelements for press-fit technology have excellent mechanical and electrical properties, making them ideal for use in harsh environments such as high temperature fluctuations or vibration. The press-fit process creates a high performance, gas-tight cold welded connection with a contact resistance of just a few μOhm. This ensures very high current carrying capacity through low resistance contact points.

PCB design

Printed circuit boards must be designed in accordance with the latest edition of IPC A 600. In the case of solid press-fit technology, the PCBs must be designed in accordance with the Würth Elektronik ICS Press-fit Specification. Special attention should be paid to hole diameter and copper thickness.

FPFT (Flexible Press-fit Technology)

Flexible press-fit technology uses flexible pins pressed into an electrically through-plated hole in the PCB. Unlike the massive press-fit technology, the pin is deformed instead of the PCB. There are many options for the shape of the pin. For example, the "needle eye" is very popular. Note, that the gas-tight contact is limited to the deformation zone of the pin.

PCB design

PCB must be designed in accordance with the latest edition of IPC A 600. In the case of flexible press-fit technology, the PCBs must be designed in accordance with the Würth Elektronik ICS Press-fit Specification. Special attention should be paid to drill diameter and copper thickness.

SMT (Surface Mount Technology)

SMT is the process by which the component is soldered to the surface of the PCB. The solder paste is applied using a stencil, and unlike to the massive press-fit technology, the solder pad is electrically connected to the different layers of the PCB via vias as standard.

PCB design recommendations

PCBs should be designed in accordance with the latest edition of IPC A 600. Footprint specifications are available.

THT (Through Hole Technology)

The THT process involves soldering solid pins into electrically plated-through holes in a printed circuit board. A distinction is made between wave soldering and selective soldering. In the former, the entire board is passed over a tin wave. In the selective soldering, the solder joints are approached individually with a tin crucible. The contact resistance of the solder joint is higher compared to the massive press-fit technology. This can affect the current carrying capacity.

PCB design recommendations

Printed circuit boards should be designed in accordance with the latest edition of IPC A 600. Footprint specifications are available.

Further information

Current carrying capacity

Current carrying capacity must always be considered in the context of the overall system. Our measurements have shown that the limiting factor is usually to be found in the layout of the PCB or the connection of external leads (contact resistance press-in zone 100-350 μΩ).

Qualification

LF PowerBasket Press-fit high current contacts have successfully passed the vibration test in accordance with ISO 16750-3:2012 4.1.2.7.2 Random Test VII.

LF PowerBasket SMD high current contacts have successfully passed the test following LV214 PG19.