Lead-free until

June 30, 2027!

Lead-free until

June 30, 2027!

The RoHS exemption 6c is expiring! Here you can find out how to switch your projects to lead-free solutions in time and what you need to consider.

The European Union is entering the final phase of the transition to lead-free solutions in the electronics industry. For decades, lead played a central role in soldering, alloys, and components. At the same time, it is well known that lead is a highly toxic heavy metal that poses serious risks to both human health and the environment.

Pressure from policymakers, society, and customers is increasing: With sustainability gaining importance and corresponding regulations being enforced, clear signals are being sent that lead-free electronics are the future standard. Stricter requirements from the RoHS Directive, the REACH Regulation, as well as other legal frameworks (such as the ELV Directive), and current developments surrounding RoHS exemption 6c, make it necessary for companies to realign their development and production processes.

This guide provides a comprehensive overview of the current status, legal frameworks, future scenarios, and practical recommendations for action.

CONTENTS:

RoHS, REACH and more

Legal lead restrictions at a glance

RoHS Directive (Restriction of Hazardous Substances)

The RoHS Directive 2011/65/EU aims to restrict the use of certain hazardous substances in electrical and electronic equipment, thereby minimizing their release into the environment. Lead is one of the substances restricted under Article 4(1), with a defined maximum concentration of 0.1% by weight in homogeneous materials. However, specific exemptions listed in Annex III allow for higher limits in certain cases, such as exemption 6c for copper alloys.

Note: All Powerelements from Würth Elektronik ICS are RoHS-compliant. The Original Powerelements comply with RoHS under exemption Annex III, 6c. The lead-free LF Powerelements are RoHS-compliant without any exemption, making them a future-proof solution.

REACH Regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals)

The REACH Regulation (EC No. 1907/2006) governs the registration, evaluation, and authorization of chemical substances within the EU. Since 2018, lead has been listed as a Substance of Very High Concern (SVHC). This results in several obligations:

- Suppliers must inform customers if articles contain more than 0.1% lead by weight (Article 33 of the REACH Regulation).

- Transparency across the entire supply chain is required, including mandatory disclosure of lead content.

- Potential future authorization requirements may apply if risks are not sufficiently controlled.

Note: Würth Elektronik ICS includes a corresponding note on delivery documents indicating a lead content >0.1% for non-lead-free Original Powerelements.

ELV Directive (End-of-Life Vehicles Directive)

The End-of-Live Vehicles Directive (2000/53/EC, ELV) limits heavy metals such as lead in vehicles to 0.1% by weight in homogeneous materials. Based on exemption 3, copper alloys containing up to 4% lead are currently permitted. A review of this exemption has already been announced for 2025.

Update 2025

RoHS Exemption 6c

The RoHS exemption 6c has currently allowed copper alloys to contain up to 4% lead by weight. This exemption has been particularly important for the automotive and electronics industries, as alternative materials do not always offer the same technical properties. The exemption was originally set to expire on July 21, 2021. However, several renewal applications were submitted on time. Due to the required review process by the European Commission, the final decision on the extension was delayed, which meant the exemption remained valid.

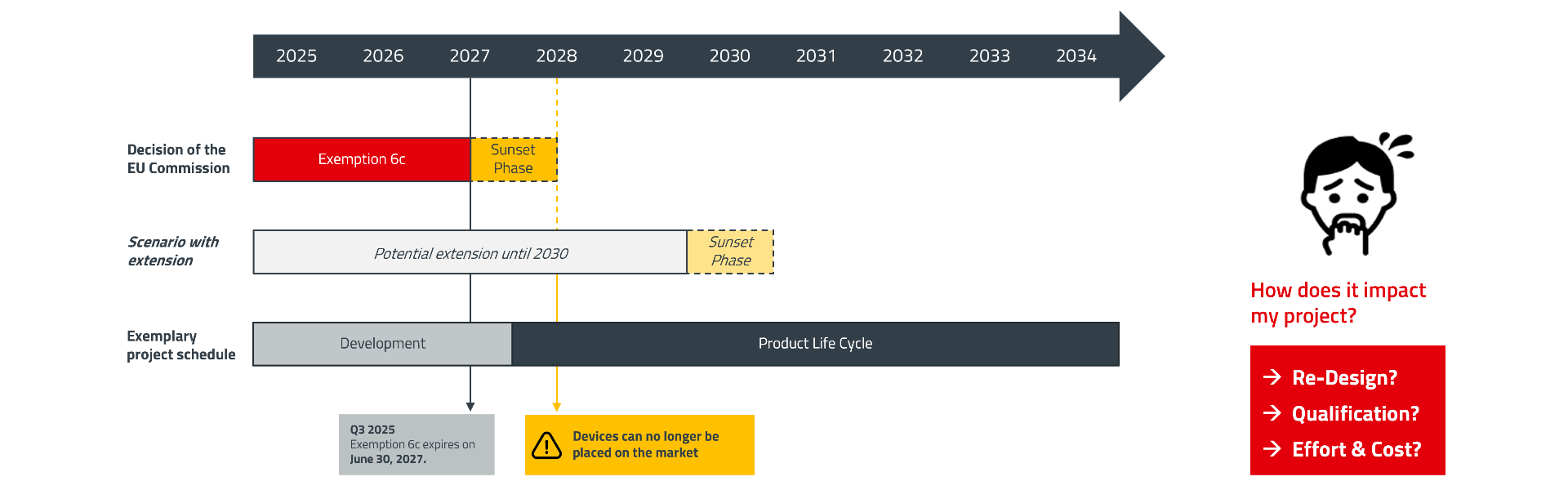

On September 8, 2025, the European Commission announced:

- The exemption will expire on June 30, 2027.

- After this date, the general RoHS limit of 0.1% lead will also apply to copper alloys.

Following the expiry, the European Commission may define a sunset period, a transitional phase of 12 to 18 months. Applicants who submitted renewal requests now have the opportunity to gather and present evidence to justify an extension of exemption 6c before the expiry date.

Prognosis

What impact does the RoHS decision have on my development projects?

For ongoing development projects, this means that redesigns, material changes, and requalifications are strongly recommended. This also applies to products intended to be placed on the market before June 30, 2027.

Impact of the EU Commission's decision on companies

- Companies must adapt materials, processes, and products in a timely manner.

- Development projects expected to remain on the market until 2030 or beyond require immediate adjustments.

- Additional costs due to redesigns and requalifications.

Potential extension until 2030

- If applicants provide sufficient technical evidence by 2027, the exemption could be extended.

- Any extension would be temporary, as the EU continues to pursue its 2030 climate goals.

- Risk: Companies relying on an extension may face sudden and significant conversion costs.

Our experts currently consider a further extension beyond these three years unlikely due to ongoing developments.

Next Steps

Actionable recommendations for affected companies

The electronics industry must make clear decisions starting in 2025. With the foreseeable end of RoHS exemption 6c on June 30, 2027, action is required.

Recommendations for Companies

- Act now: Immediately analyze all lead-containing materials and components in your portfolio.

- Evaluate alternatives: Begin transitioning to lead-free components and technologies early.

- Engage suppliers: Collaborate to develop solutions that ensure compliance.

- Risk management: Assess scenarios and integrate transition periods into development cycles.

- Communicate sustainability: Actively promote lead-free electronics as a quality and environmental advantage.

Outlook

In light of the EU’s 2030 climate goals and the global shift toward a circular economy, one thing is clear: lead has no future in electronics! Companies that consistently switch to alternatives now will secure regulatory compliance, economic stability, and a clear competitive edge.

Let it be lead-free!

Let it be lead-free!

The future of power electronics is lead-free – just like the lead-free LF Powerelements from Würth Elektronik ICS!

Services

WE support you in switching to lead-free components

FAQs on lead restrictions

For all categories of equipment, applications for renewal of the exemption were submitted in due time (at least 18 months before the expiry of the exemptions under Article 5 (5) of the RoHS Directive. Until the EU Commission decides on these applications, exemption 6c will remain valid.

Due to the current high use of leaded brass, an early start of the sunset phase and thus a ban on lead does not seem realistic at this time. Therefore, a further extension is very likely. This will then be retroactive to the respective presumed phase-out date and will presumably differentiate between the individual appliance classes.

The Öko-Institut has issued a recommendation to extend exemption 6c for all equipment classes until July 21, 2026. The "RoHS Umbrella Project" recommends an extension for selected equipment classes (8, 9 & 11). The analyses, reports and recommendations will serve as the basis for a decision by the responsible EU Commission. This decision is currently still pending.

We as Würth Elektronik ICS assume that there will be no further extension after July 21, 2026.

From the point of view of the experts at Würth Elektronik ICS: Absolutely! Many projects have a total duration of several years from development to "end of life", whether in the automotive, electronics, industrial or commercial vehicle sectors. With lead-free LF Powerelements, you are ready for the future. Costly re-qualifications are avoided, process reliability for new developments is created and well-known OEMs, who already demand and successfully use lead-free products, can be served without any problems.

The global trend is clear: the use of lead is being steadily reduced. Examples include:

WEEE (Waste of Electrical and Electronic Equipment)

To reduce or completely avoid waste from electrical and electronic equipment, there is the WEEE Directive 2012/19/EU. Among other things, it provides for recycling and reuse, and creates the legal framework to collect the equipment and properly recycle its raw materials properly recycled. Although the directive does not ban toxic metals and heavy metals, it does ensure that the cost of their disposal continues to rise.

Other similar regulations are being implemented around the world, e.g.:

California Proposition 65

Companies operating in California (USA) must be aware of and comply with the guidelines of California Proposition 65 (Prop 65), also known as the Safe Drinking Water and Toxic Enforcement Act of 1986. The law lists more than 800 chemicals "known to the state to cause cancer or birth defects and other reproductive harm." Lead is on the Proposition 65 list. Prop 65 is a "consumer's right to know." Unless companies are exempt from compliance, they must provide a "clear and conspicuous warning" if their products may expose people to the listed chemicals. Similarly, they must warn the public if they discharge listed chemicals into drinking water sources.

China RoHS 2 (GB/T 26572-2011 Label: SJ/T11364-2014)

A concentration limit of 0.1 % lead applies to all electrical and electronic products covered by the directive in the People's Republic of China. If this value is exceeded, labeling is required for B2C business.

Korea RoHS

South Korea passed the "Act for Resource of Electrical and Electronic Equipment and Vehicles" - commonly referred to as Korea RoHS - back in 2007. This law largely adopts the EU's directives RoHS, WEEE and ELV (End-of-Life Vehicles Directive).