Powerelements in drive technology

Powerelements in drive technology

Pluggable contacting in confined spaces

Powerelements in motor drives by Keep Motion

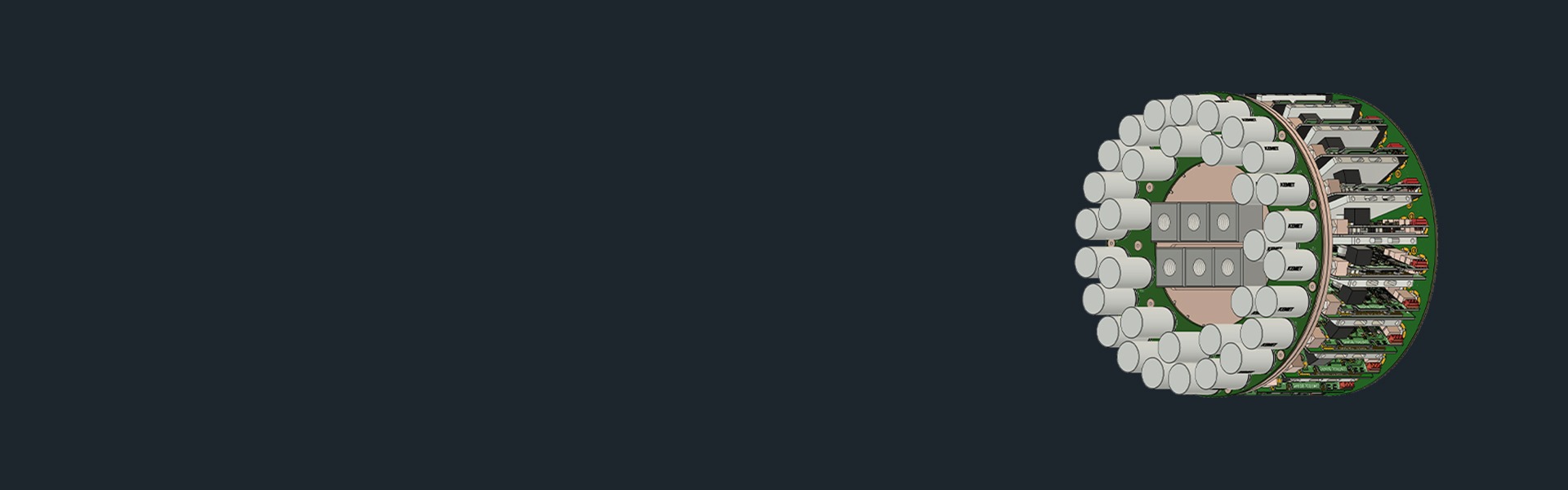

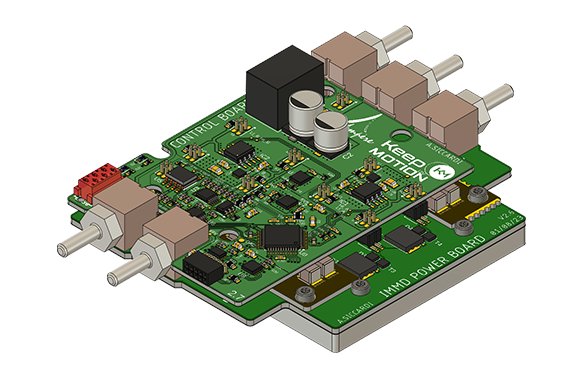

As part of a research project, Keep Motion developed an innovative, integrated and modular motor drive (IMMD) for a powerful 48 V / 85 kW permanent magnet synchronous motor (PMSM) with an open winding. For this challenging project, the company chose Powerelements from Würth Elektronik ICS, which were characterized by their compactness and electrical performance.

Project process and component selection

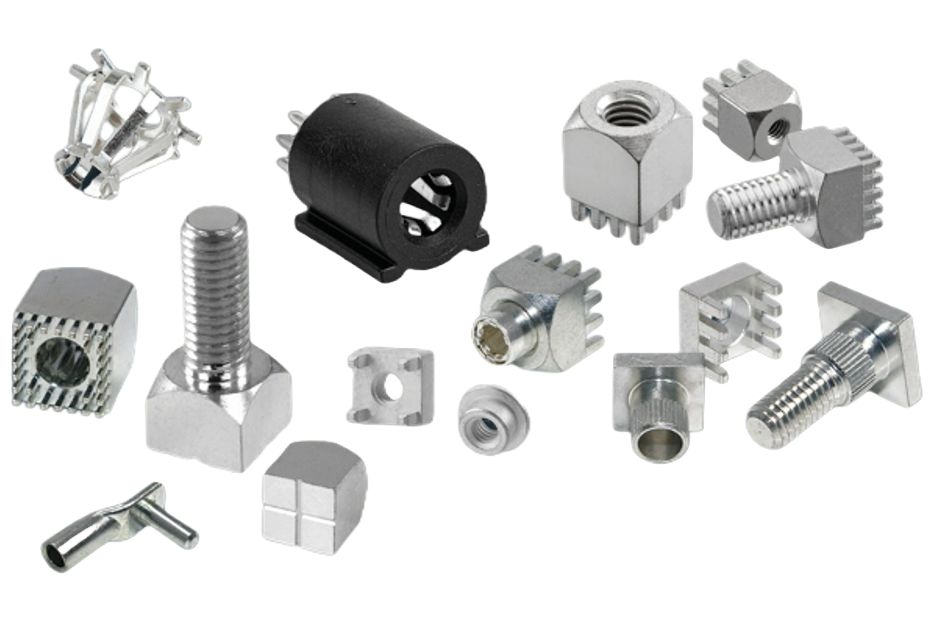

During the research phase of the project, Keep Motion relied on Powerelements from the standard portfolio to find a solution. The choice fell on the two product groups PowerOne and LF PowerBasket:

- PowerOne SMD bush

- PowerOne bolt

- PowerOne press-fit bolt

- LF PowerBasket SMD

These components were selected due to their excellent suitability for confined spaces.

Technical implementation

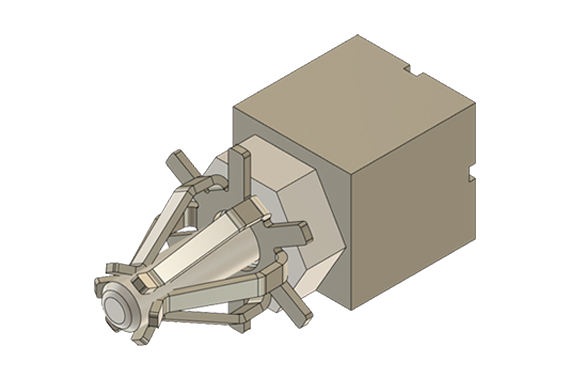

Each motor coil is supplied with a current of up to 150 A by a single-phase inverter. The inverters were designed so compactly that they can be placed directly above a stator pole.

Power supply and connection

Due to space restrictions, Keep Motion opted for horizontal processing of the PowerOne SMD as base elements. This unconventional application was made possible by the high precision and surface quality of the components. For series production, a customized solution with a PowerOne SMD with a side hole is possible in order to be able to respond even more precisely to the available space conditions.

The PowerOne bolts, which are screwed to the soldered PowerOne SMD bushes, fulfill two important functions:

- They supply the IMMD with power.

- They enable a pluggable connection of the inverter to the motor backplane and the 48 V busbar.

Board-to-board connection on the opposite side

The LF PowerBaskets are used on the opposite side. These are soldered directly to the busbar and the motor rear panel, which ensures a reliable and efficient connection. The position tolerance of the LF PowerBasket of up to 0.6 mm was not utilized in this application. The LF PowerBasket was used in the opposite direction to the originally designed plug-in direction, in which Keep Motion arranged the springs upwards. This is also technically possible, but the advantage of the above-mentioned position tolerance when mating with the counterpart is lost.

Thanks to this well thought-out combination of different Powerelements, Keep Motion has succeeded in developing a highly efficient and compact motor drive that meets the demanding requirements of modern electric drives.

Keep Motion uses the following Powerelements in its product

The key factors in the decision to use Powerelements from Würth Elektronik ICS were

- Compact and pluggable solution for highly limited installation space

- Customized development of the PowerOne bolt, suitable for the PowerOne bush and the LF PowerBasket

Keep Motion was also convinced by the comprehensive services

- Competent project consulting

- Customized development