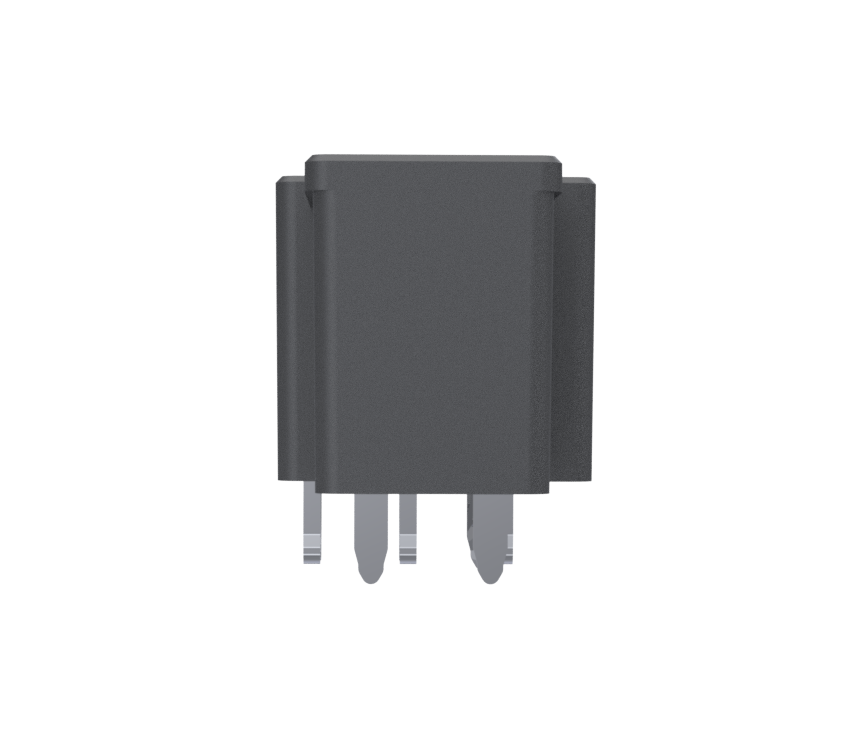

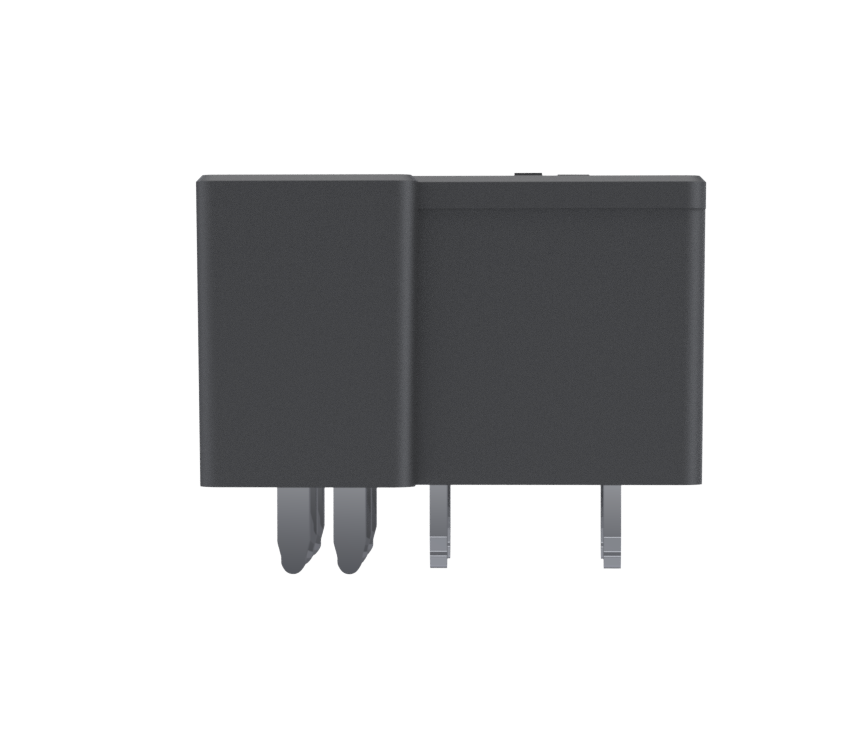

Processing options for PowerSocket Relay

MPFT (Massive Press Fit Technology)

Massive press-fit technology is the process of pressing solid pins into an electrically plated-through hole in a printed circuit board. Powerelements for press-fit technology have excellent mechanical and electrical properties, making them ideal for use in harsh environments such as high temperature fluctuations or vibration. The press-fit process creates a high performance, gas-tight cold welded connection with a contact resistance of just a few μOhm. This ensures very high current carrying capacity through low resistance contact points.

PCB design

Printed circuit boards must be designed in accordance with the latest edition of IPC A 600. In the case of solid press-fit technology, the PCBs must be designed in accordance with the Würth Elektronik ICS Press-fit Specification. Special attention should be paid to hole diameter and copper thickness.

Further information

Current carrying capacity

The current carrying capacity of a press-fit connection must always be considered in the context of the overall system. The press-fit zone itself has an extremely low contact resistance, so that the limiting factor is usually to be found in the layout of the PCB or the connection of external supply lines.

Max. permissible contact temperature 130°C (blade contact to PowerSocket contact)

Qualification

PowerSocket Relay have successfully passed the vibration tests and the mechanical shock test in accordance with the ISO 16750-3 standard.

Vibration test according to ISO 16750-3:2012 4.1.2.7 Random Test VII.

Mechanical shock test according to ISO 16750-3:2012 4.2.3 Severity 2.