Powerelements in the railway industry

Powerelements in the railway industry

Unique expertise in PCB contacting technology

Powerelements in Wabtec’s all-electric locomotive

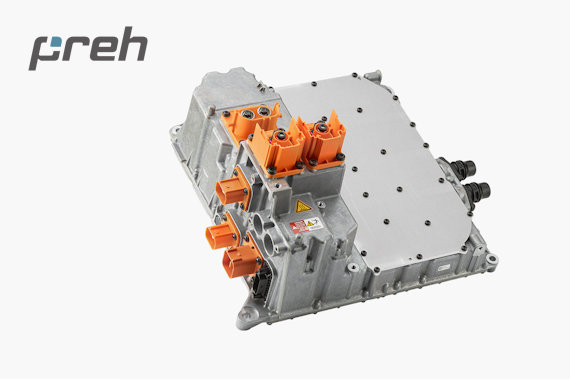

Electrification of mobility is advancing worldwide – not only in the automotive sector, but increasingly in other industries as well. A major milestone was reached in rail transport in October 2023: Wabtec unveiled a fully electric locomotive. This machine was built, among other components, using battery chargers and inverters from Wabtec’s subsidiary Faiveley Transport. At the heart of this technology: powerful Powerelements from Würth Elektronik ICS.

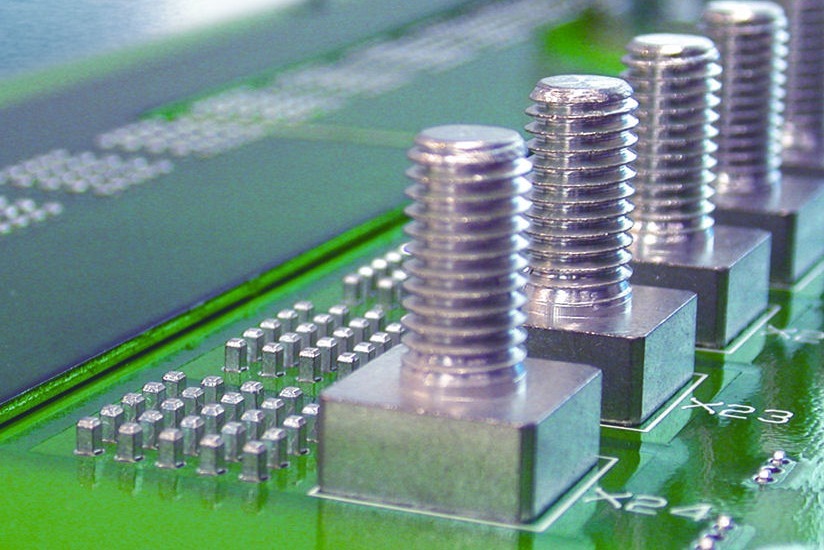

Faiveley Transport uses these high-current contacts to ensure reliable contacting of converters(such as battery chargers and inverters) in the new electric locomotive, as well as for connecting IGBT modules to the printed circuit board. In particular, Faiveley benefited from Würth Elektronik ICS’s unique expertise and many years of experience in contacting IGBT modules.

Wabtec is one of the world’s leading providers of equipment, systems, digital solutions, and services for the transportation sector, accelerating the future of mobility with innovative technologies.

Faiveley Transport manufactures electrical traction equipment, pantographs, and trolleybus collectors, and is therefore deeply rooted in the core business of its parent company.

Faiveley uses the following Powerelements in its products

Compelling arguments for Faiveley

Unique Solutions

The decision to use Powerelements from Würth Elektronik ICS was driven by the following key factors:

- A unique solution for connecting IGBTs and converters to the PCB

- Quick selection of the appropriate Powerelements thanks to the clear and structured presentation of available components

Comprehensive Services

Faiveley Transport also chose to collaborate with Würth Elektronik ICS due to the company’s extensive range of services:

- Excellent consulting by dedicated contact people

- Intensive support during the design-in process

Extensive Expertise

Faiveley Transport also gained added value from the long-standing expertise of Würth Elektronik ICS:

- Press-fit technology solutions are particularly well-suited to meet the demanding requirements of the railway industry.

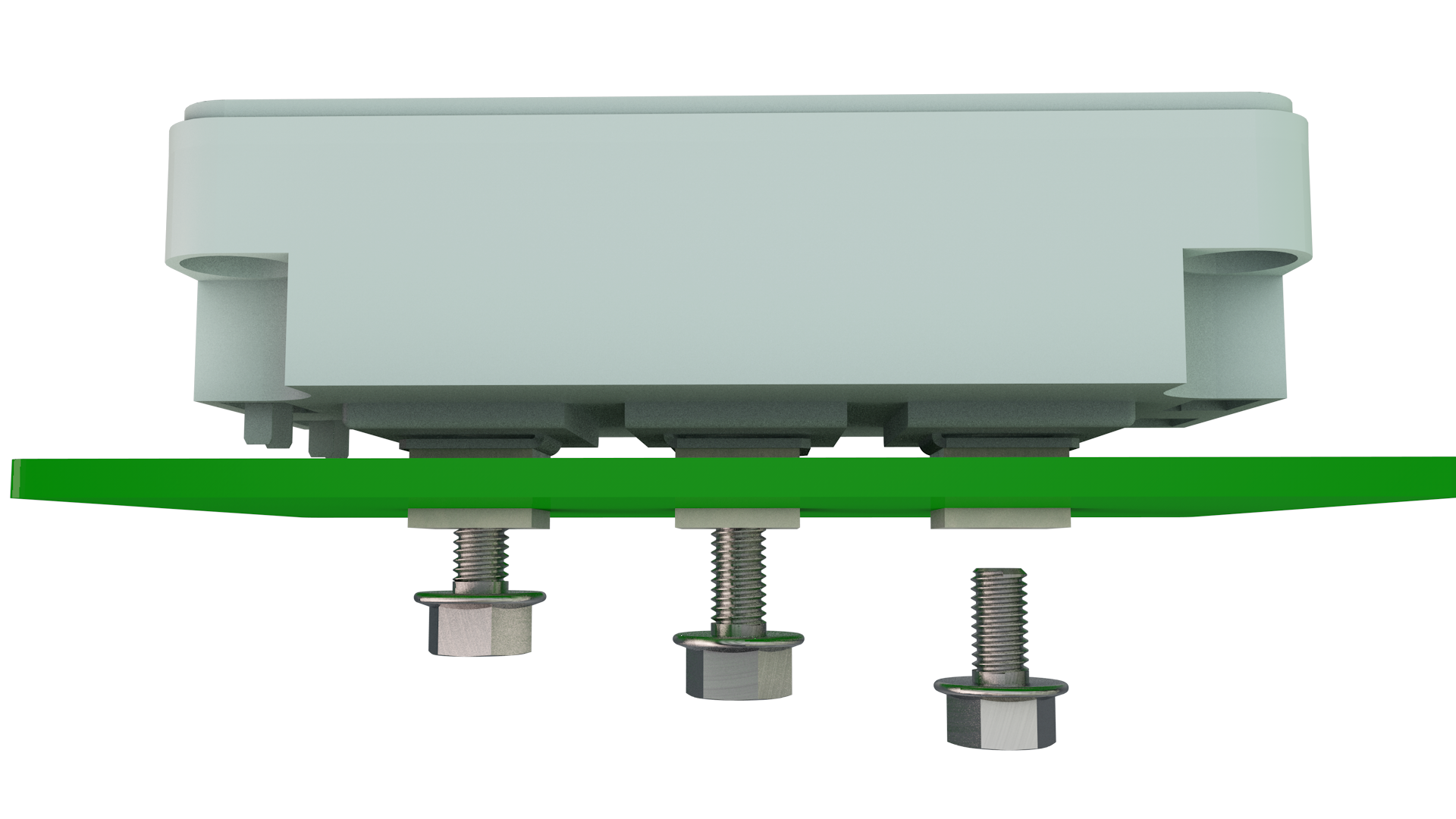

(LF) PowerTwo

Alternative mounting options IGBT modules

IGBT modules can be mounted even more easily using (LF) PowerTwo. This two-piece Powerelement consists of a base element and a press-in element. The base element is press-fitted into the PCB, after which the push-in element is inserted into the base. This allows for secure mounting through the PCB without applying mechanical stress to the printed circuit board itself.